At 19: 21 on July 7, 2020, the first high-speed Internet airplane successfully made its first flight as the flight QW9771 of Qingdao Airlines landed safely at Chengdu Shuangliu International Airport, opening the digital mileage of new infrastructure construction of CAAC!

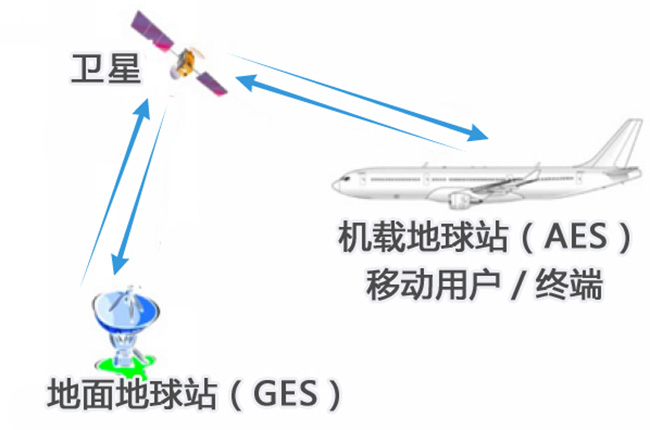

GRGTEST was responsible for all airworthiness certification tests and appraisals before the first flight of the airplane. At the same time, with the comprehensive service mode of "scientific research and design + system airworthiness test + whole-airplane on-site TPED test", GRGTEST participated in the analysis of EMC and reliability design before the installation of airborne satellite communication products, which can assist in the system networking and airworthiness certification (FAA + CAAC), and assist Qingdao Airlines, China Satcom and FTS to successfully make the first joint flight, providing testing technical support for the construction of the "high-speed Internet in the air + air-to-space integrated satellite networking"!

GRGTEST is once again to protect the safety of China's civil aviation after C919 and AG600!

How awesome is the first high-speed Internet airplane of China?

↓

The first air Internet aircraft

with independent intellectual property rights in China

has broken

the long-term monopoly situation of foreign manufacturers in this field.

The XstreamSAT system

is installed to

connect the first and the only one Ka band high-throughput satellite (ChinaSat No. 18) in China.

The bandwidth rate of the single airplane can reach 150Mbps.

It means that

even if you and your teammates are separated from each other,

you can still play the game

with four people

and become the winner smoothly

Security is undoubtedly the most important

for civil aviation

There are millions of components in large airliner,

thus the electromagnetic environment of airborne electronic equipment is complex.

It is necessary to carry out the strict inspection of the modified airplane

in order to ensure that the equipment on the airplane

without any interference

And GRG Test was also lucky

to have made a little bit of (glorious) contribution to it

————————————————

(1) May 2019:

Entrusted by FTS (Beijing) Technologies Co., Ltd. (hereinafter referred to as FTS) and the Federal Aviation Administration (FAA) of the United States, GRG Test was responsible for the airworthiness certification test for DO-160G airborne satellite communication system. The company took advantage of national integrated management and control to deploy laboratory resources in Xi'an, Guangzhou and Shenzhen, so as to immediately establish the FAA airworthiness test project group, and set up the technical backbone team to prepare the test scheme for the full security.

(2) May - June 2019:

Overcoming the short test cycle, heavy tasks, verbal communication, technical difficulty and other problems, the technical team worked in three consecutive shifts in order to complete the designated DO-160 test (including electromagnetic and environmental tests) of the 4 component products of the system.

(3) December 2019:

The technical team conducted a T-PED test on the Airbus A320 airplane of Qingdao Airlines after the satellite communication system was modified at the Jinan Yaoqiang International Airport. Tests of the front door coupling and rear door coupling were carried out for the added WiFi system in accordance with the DO-363 standard and the requirements of FTS, covering systems tests of WiFi, GPS, HF, VHF, VOR, ILS. As there were no similar cases that can be used in China, the selection of test position, reasonable determination of the test frequency band, selection of sensitivity criteria and tailoring of test standards were all new challenges for the technology team of GRGTEST. At the same time, the test can only be carried out at night due to the control of the airport in the daytime. Strong wind, low temperature and continuous all-night work are all physical and psychological tests for testers.

According to the opinions of FAA airworthiness experts, as the technical team constantly adjusted the test parameters during the test, and assisted the crew to check the performance of airborne equipment, the external interconnection of all required test ports of the system was finally realized; all the results met the requirements of FAA and the task was successfully completed after continuous fighting in the whole night.

From "zero" to "integration",

many difficulties have been overcome

Standards were strictly observed

to protect the safety of "all corners" in the whole cabin

The professional performance of the GRG Test technology team

has also been recognized by customers

The commendatory letters from the customer

The roc flies up with the wind and soars into the sky for thousands of miles

GRGTEST will continue to

help the speeding-up of high-end equipment localization,

and play a technical support role in improving the quality

and efficiency of new civil aviation infrastructure

We wish China's civil aviation industry to have a higher, farther and broader future!

————————————————

GRGTEST has built a comprehensive measurement and testing service in the field of aviation measurement and testing, meeting the test requirements of airborne products of civil airplanes. It can provide industry-leading measurement and testing services for airplane manufacturers, components suppliers, airlines and aviation research institutions, and can help all units to complete the quality control of the whole life cycle of the products from the design to the finished production.

The company has been authorized and approved by the test service provider of COMAC, passed the on-site DO-160 test review and T-PED assessment and test of FAA and EASA, and obtained the relevant qualification of international airworthiness testing project. It has also undertaken the related airborne system equipment test projects of China large aircraft, the Federal Aviation Administration (FAA) and European Aviation Safety Agency (EASA), accumulating many years of technology and solid experience in product quality control in the aviation industry.

Click on the right for the online consultation.

(Part of data are from: Qingdao Airlines, QTV-1 and CAAC News)