Welcome to GRGTEST!

Service Hotline 400-602-0999

Failure analysis

Through a comprehensive and systematic analysis, the failure mode and failure mechanism are determined to help improve reliability.

Online

Comprehensive environmental reliability test

It can provide comprehensive environmental testing for automotive vehicles and parts, aviation aircraft and various products.

Online

ROHS detection

Provide testing services for environmental protection requirements of electrical and electronic products including EU RoHS and China RoHS.

Online

Textile testing

Provide enterprises with testing services for textiles, clothing, garment accessories, leather and other textile products.

Online

Drinking water testing

Provide the drinking water detection program of centralized water supply and secondary water supply.

Online

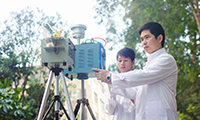

Ambient air and exhaust gas detection

Provide testing services for ambient air, organized exhaust gas from factories and enterprises, and unorganized exhaust gas.

Online